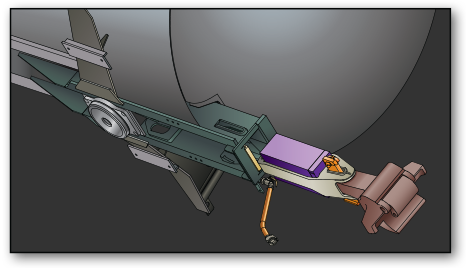

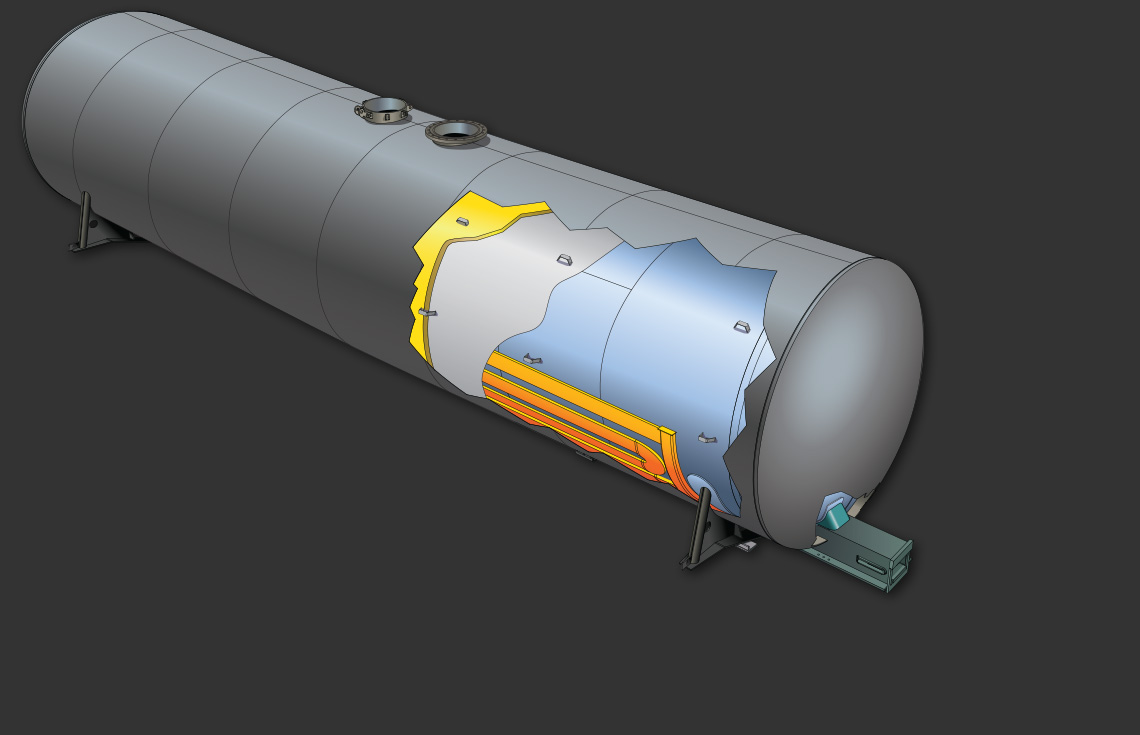

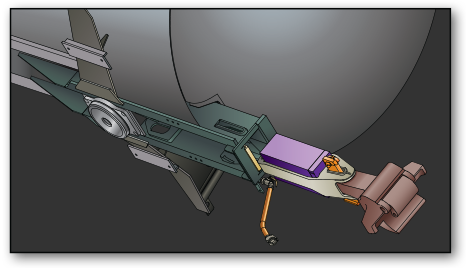

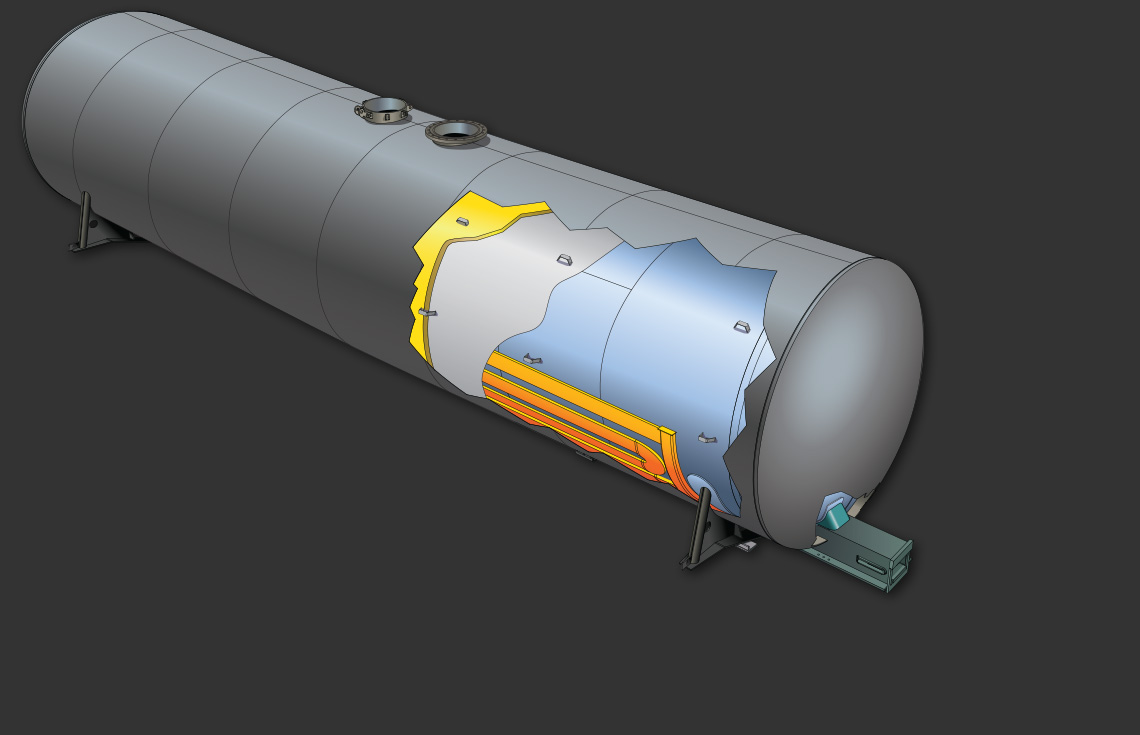

Draft gears and couplers are installed into the tank car's draft sills at the UTLX Manufacturing plant. Each M901E draft gear acts like a shock absorber to cushion the expected impact forces introduced when the train starts and stops. The buff and draft forces in a loaded train are massive. In addition, when trains are made up in a classification yard, coupler engagement between a rolling car and a stationary car can generate as much as 1,250,000 pounds of force in an instant. The draft gear must dissipate the impact to protect the car. Draft gears and couplers are wear items that can be replaced by both UTLX Field Services and full-service UTLX Repair Shops.

Type E and Type F couplers with top and bottom shelves are an FRA requirement for tank cars. The coupler design guards against vertical disengagement in the case of a derailment or another unpredicted event. Top and bottom shelf couplers are a cost-effective means to inhibit couplers overriding each other which otherwise might damage the car's end platform or possibly the tank itself. Double shelf couplers only release upon actuation of the uncoupling rod.

Polymer wear liners – or coupler carriers – allow side-to-side movement of the coupler and minimize wear to metallic draft sill components. As tank cars are designed to negotiate 13-degree curves, the coupler carrier allows necessary movement of coupler components so that your products arrive safely to their destination in your UTLX tank car.