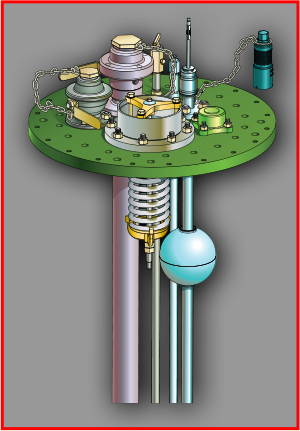

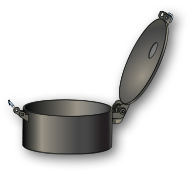

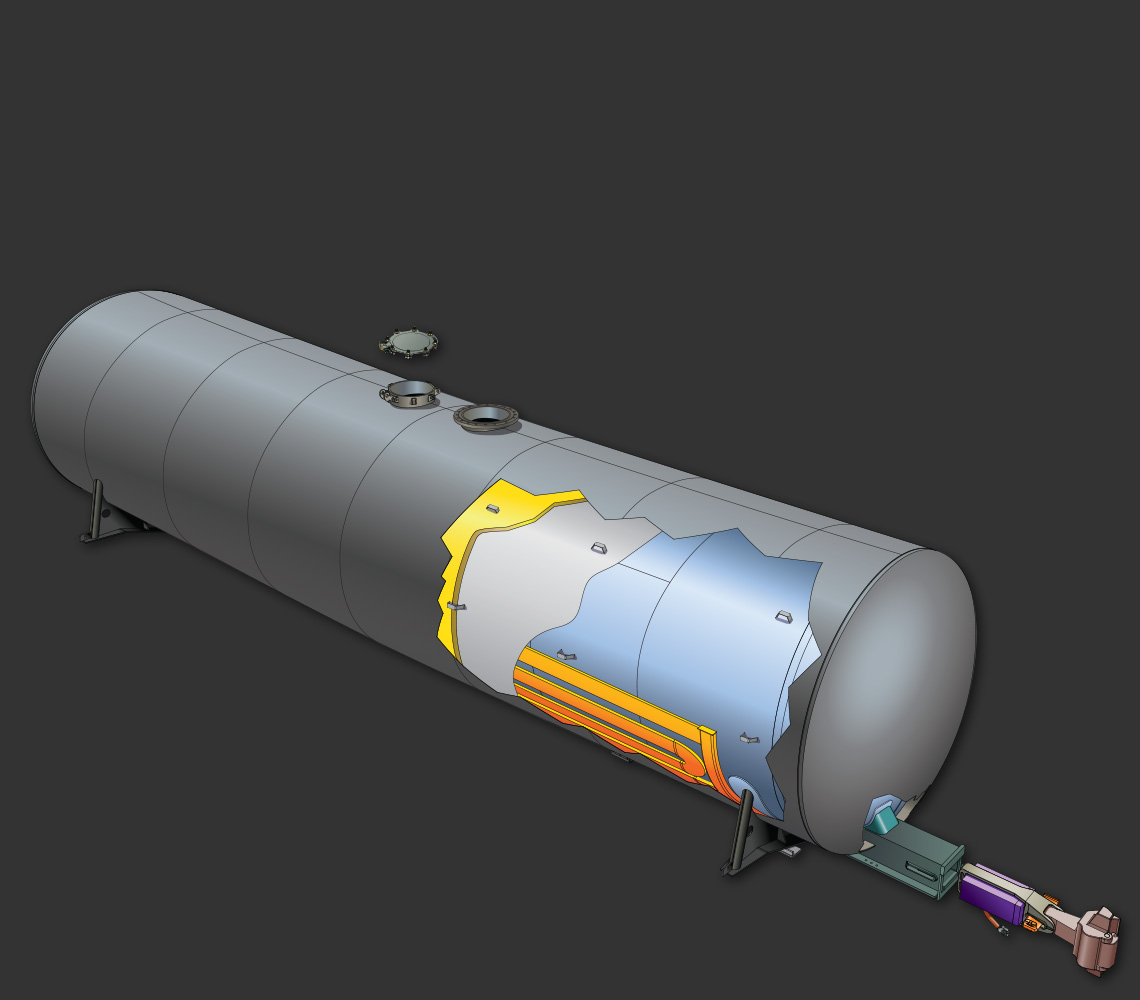

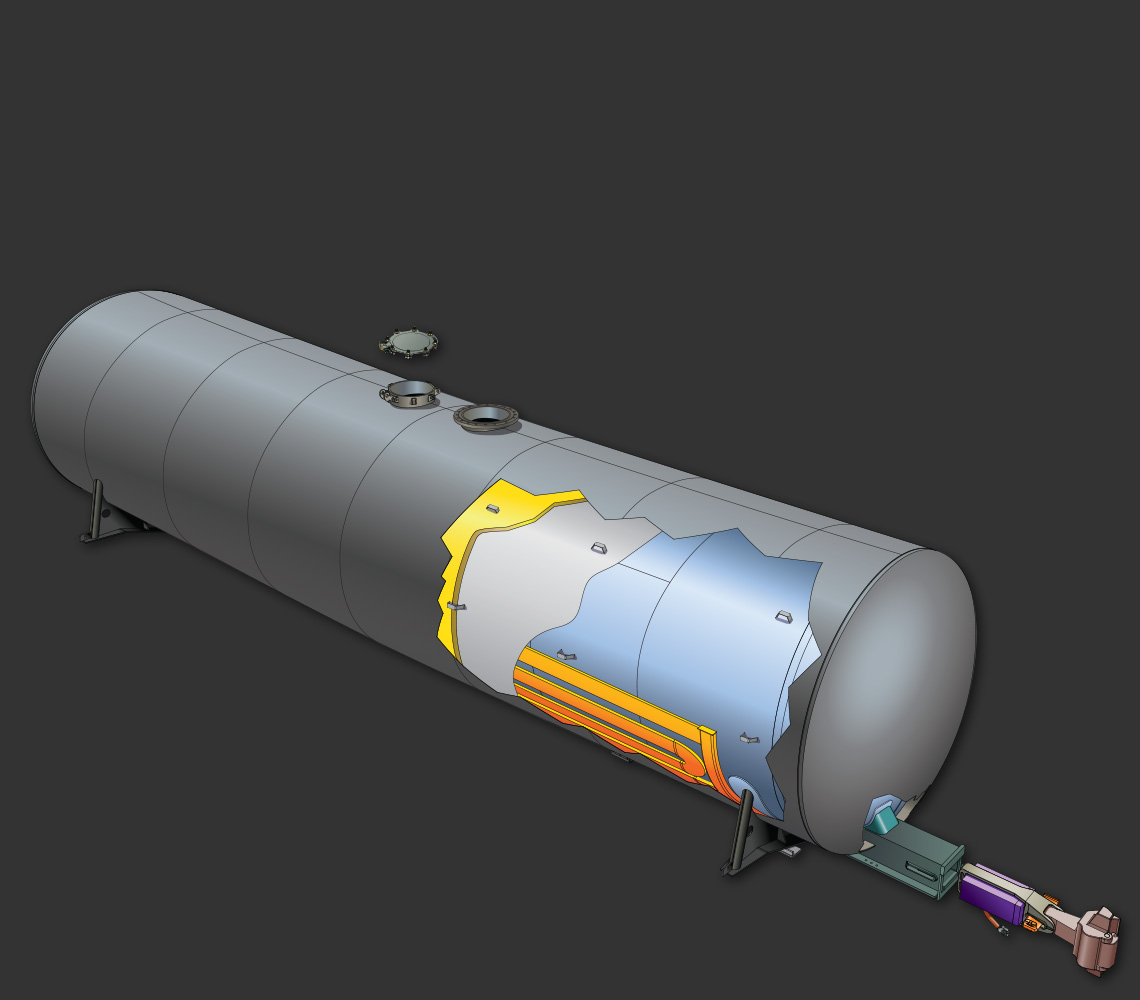

The DOT 117J100W general purpose tank car produced by UTLX Manufacturing is equipped with a protective housing to safeguard the fittings, valves, and components mounted on the fittings flange. The housing is engineered to withstand AAR design loads and takes into account multi-directional impacts to which tank cars might be subjected, as well as the strength of the nozzle and the tank shell.

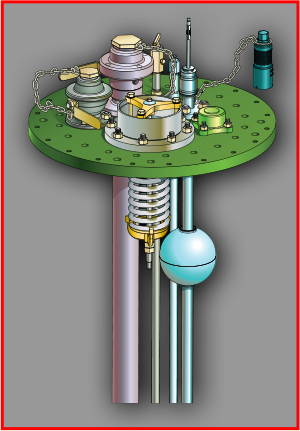

The standard top fittings arrangement consists of a 2” vapor valve and a 3” liquid valve, which is connected through the fittings flange to a siphon pipe. The siphon pipe extends to a sump at the bottom of the car. The flange also mounts a pressure relief valve and a vacuum relief valve. Accessories such as a gauging device, thermowell, and/or a sample line may also be installed on the fittings flange.

Valves and fittings designed by UTLX include:

UTLX Basic Designs specify valves manufactured in the USA at McKenzie Valve & Machining Company, although alternate valve designs are applied upon specific requests. Union Tank Car Company maintains a North American-wide support network including engineers and technicians to provide AAR-certified service for all of your tank car needs.